Many modern machines have a plastic type of way liner called TURCITE. It is a very durable material that wears very well. When the way lube is lacking or contamination enters the lube system the turcite tends to lose its effectiveness, becoming soft and gummy in nature, thus separating from the machine casting. Although many popular thicknesses are available, the correct way is to machine it to the desired thickness. This allows for a nice mating surface, to work in harmony with your machine slide ways. It is imperative the lube system is evaluated for its capabilities of delivering the proper amount of lube to the NEW TURCITE. Being Shop Based and Field Mobile, RAKO Inc can offer a COMPLETE TURN KEY Job , depending on your desires.

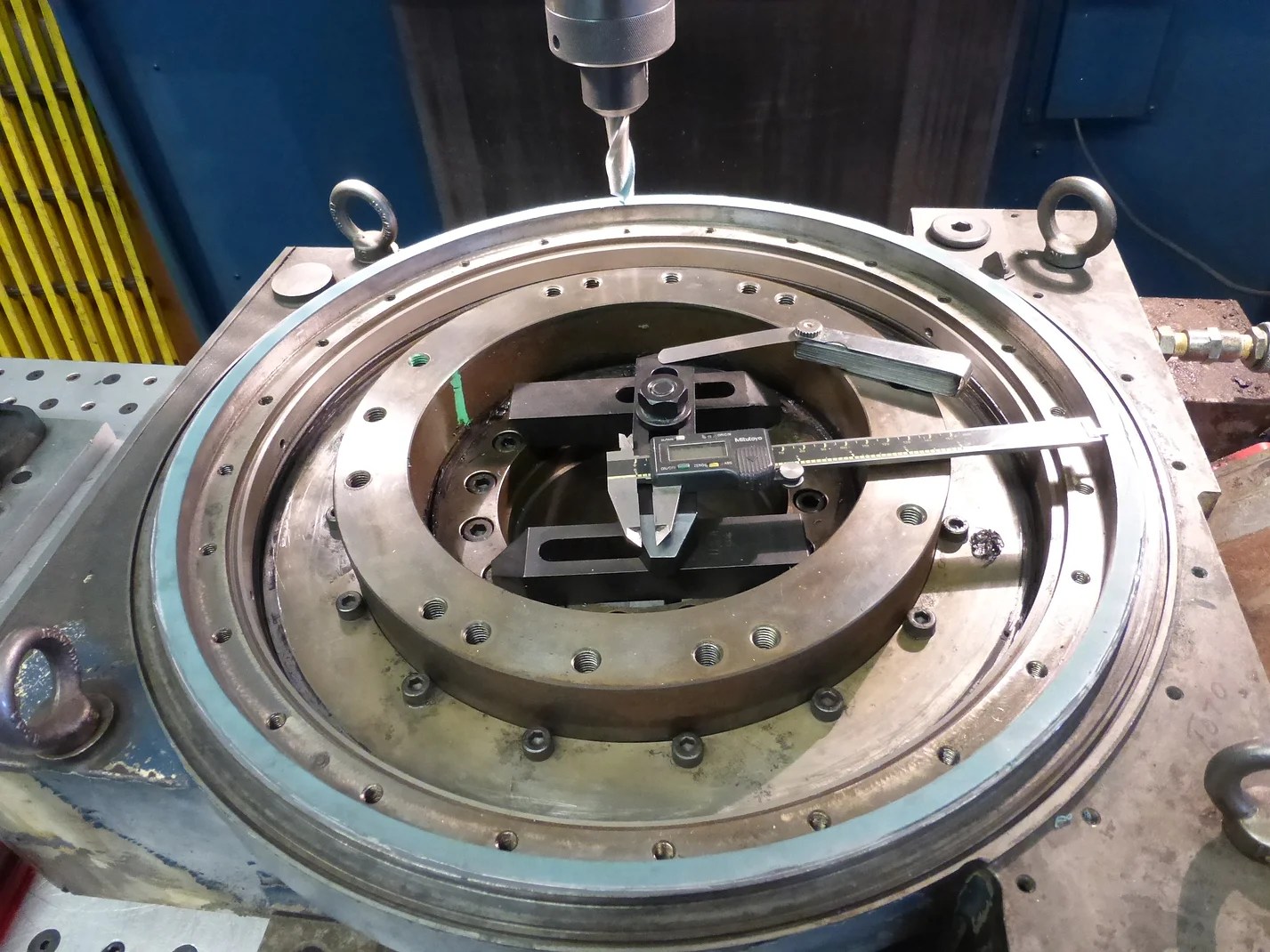

This type of machine may have ball screws for the travel movements of the table.

The measured accuracy of the turcite project may be reflective of the quality of the ball screws and nuts, as well as the thrust bearings. If the turcite and table area was lacking lube, it is a highly probable the ball screw was challenged as well.