RAKO Inc provides field repair services for the Large Engine Lathes and the Oil Field Type HOLLOW Spindle machines. Over time the Spindle Bearing become worn and will need adjustment to provide the rotational accuracy desired. Should noise and POOR Finish become an issue, the Main Bull Gears and Speed Reducing Shafts and Sliding Gears and Bearings may need replacement. Another common issue is gear shifting or speed changes, being able to select the desired speed. This may be from a rotational cam action, positional handles to a push button preselector. During crashes the sliding speed changer shafts can become twisted, NOT allowing the gears to position correctly to achieve the desired spindle speed. A Field Service Call could do an in-depth evaluation of the troubled area and provide options of choice.

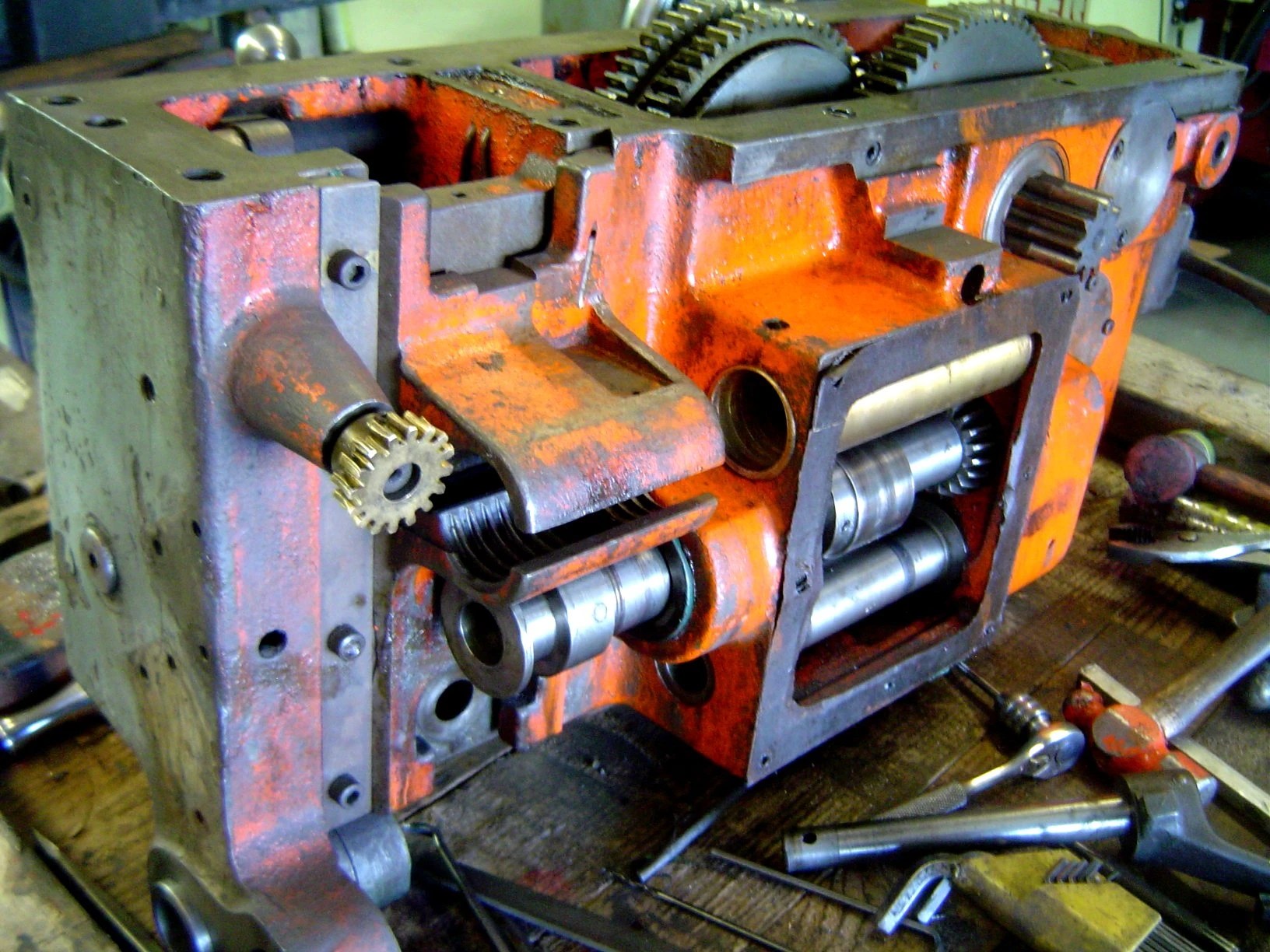

Quick Change Feed & Threading Gear Box Repairs

Modern Lathes are equipped with a quick change selector box to choose the desired feed or threading pitch. A FAILURE has occurred when the selected feed or thread range fails to produce a rotational response to the feed rod or the threading lead screw. Most Failures occur due to worn keys, overloaded conditions (Broken Shear Pin), stripped gear teeth, or from a failed jaw clutch. Should this be the case, the Quick Change Gear Case would need to be removed to complete the required repairs. A Field Service Call could do an in-depth evaluation of the troubled area and provide options of choice.